KoolDuct Ductwork Features and Benefits

Kingspan KoolDuct offers many benefits that give you the competitive edge on your next project. Listed below are ways KoolDuct can improve air distribution for you and your customers.

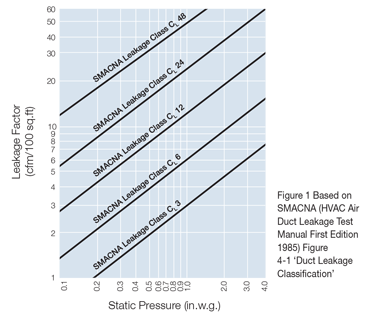

Lowest Air Leakage of Any Duct Work on the Market

Benefit from Reduced Heating and Cooling Loads

With the construction standards in place for the Kingspan KoolDuct System, air leakage can be miniscule when compared to ductwork made from insulated sheet metal. Ductwork made of KoolDuct can easily achieve SMACNA Class 3. Significant energy savings come from less air leakage by cutting down both fan horsepower and the energy usage of heating and cooling systems.

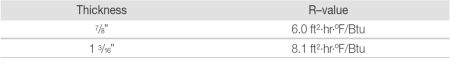

Unmatched Thermal Performance

Highest R Value to Size Ratio on the Market

With a thermal conductivity (k-value) of 0.146 Btu·in/hr·ft²·ºF at 50ºF (ASTM C 518), Kingspan KoolDuct achieves one of the lowest rates of any commonly used insulation material. A low thermal conductivity requires less space to achieve the desired thermal performance. KoolDuct's installed thermal resistances (R-values) for the available panel thicknesses are listed below:

Kingspan KoolDuct Features and Benefits - In-Depth Informational Presentation

Lightweight Labor Advantage

Reduce Installation Costs

Ductwork fabricated from the Kingspan KoolDuct System canweigh a fraction of insulated sheet metal; this means less expensive handling costs, lower transportation costs, fewer required supports and easier installation. KoolDuct removes the need to wrap the ductwork because it is pre-insulated. One worker can do much more with less weight to work with.

Resistant to Fire and Smoke

View Video Demonstration

The Kingspan KoolDuct® System panels have a great resistance to burning and spread of flame. When compared to rigid polyurethane (PUR) or rigid polyisocyanurate (PIR) insulations, Kingspan KoolDuct comes out on top with low spread of flame and almost a complete absence of smoke when subjected to a flame source. KoolDuct's insulation core is thermoset and does not melt, drip or produce flaming droplets, unlike thermoplastic materials. Not only that, but Kingspan KoolDuct successfully passes the UL 181 Burning Test and does not exceed flame spread/smoke developed indices 25/50 (ASTM E 84 / UL 723).

Code Compliance & Approvals Exceed SMACNA Duct Phenolic Construction Standards

Ductwork fabricated from the Kingspan KoolDuct® System satisfies the requirements of ANSI/ASHRAE/IESNA 90.1:2007, IECC 2003, 2006, 2009 & 2012, IMC 2009 and other major national specifications. KoolDuct complies with the requirements of NFPA Standards 90A & 90B and is UL Listed as a Class 1 Air Duct to Standard for Safety UL 181 when fabricated using: Kingspan KoolDuct® panels faced on both sides with factory applied silver aluminum foil; the aluminum grip flange and / or tiger jointing systems; and an aluminum foil vapor barrier tape that is UL Listed to Standard for Safety UL 181 A-P.

Moisture Resistant Closed Cell Technology

Industry Leading Performance

Kingspan KoolDuct® is made of a closed cell structure, making it highly resistant to moisture penetration and wicking. Additionally, the factory applied aluminum foil facing also provide a vapor barrier and reduces the risk of any water absorption.

Improves Indoor Air Quality

Preferred in Health Care Environments

Air flowing through Kingspan KoolDuct ductwork is distributed over sealed aluminum surfaces. This minimizes the risk of loose fibers entering the air. In addition to this, Kingspan KoolDuct ductwork has a non-fibrous insulation core, is odorless and non-tainting. KoolDuct panels pass the UL 181 mold growth test and do not provide food value to rodents and vermin.

Zero Ozone Depletion Product

Environmental Awareness is Built Into Our Product

Kingspan KoolDuct® panels are CFC/HCFC-free and manufactured with a blowing agent with zero Ozone Depletion Potential (ODP) and low Global Warming Potential (GWP). We can significantly reduce our carbon footprint and impact on our environments by employing better methods to manufacturer and fabrication!